TACOM HQ®

Command Results

CAGE 834B9 SAM GHMFLBP9GGM3

“Never forget that your weapon was made by the lowest bidder." - Unknown

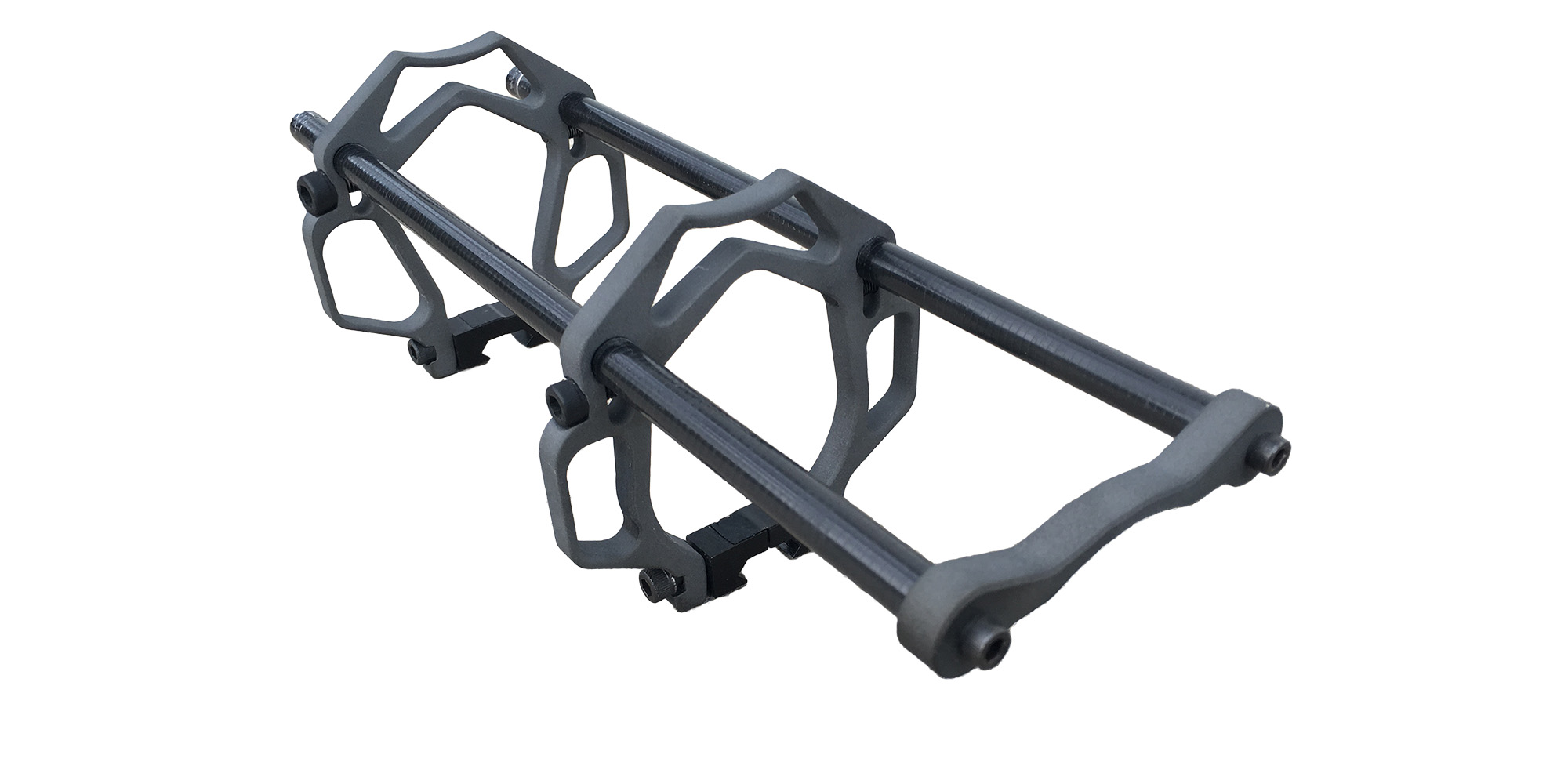

Armor Optic

Tactiholics

INTEL

• Safeguard optics and your zero.

• Ergonomically engineered for minimal visual and optic control interference.

• Weighs 6 – 12 oz. (varies upon length and selected add-ons)

- Advantages

- Limitations

- Durability

- Installation

• Braces serve as a roll-cage to isolate optics from external forces.

• Fits around setup to prevent having to detach and re-zero.

• Micro

6061 Aluminum

L 0.38″ x W 4.00″ x H 3.76″ (from top of rail)

L 10mm x W 112mm x H 96mm (from top of rail)

• Macro

6061 Aluminum

L 0.38″ x W 4.40″ x H 4.11″ (from top of rail)

L 10mm x W 112mm x H 104mm (from top of rail)

Type II High Impact PVC

L 0.75″ x W 4.40″ x H 4.11″ (from top of rail)

L 19mm x W 112mm x H 104mm (from top of rail)

Advantages

• Focus on your mission, not your rifle.

• Prevents becoming a liability.

• Protect optics at minimal expense.

• Ideal for schoolhouses and squads with finite budgets.

• Armor Optic universally fits most scopes, thermals, and NV.

• Available in two sizes: Micro and Macro. See ‘INTEL’ for specs.

Other functions:

- Camouflage attachment

- Carry-handle

- Brace against a car door, building, window, or under a vehicle.

- Lanyard(s) attachment for HELO transport / security

- Fast-roping

- SNOT

- SPIES

- Airborne operations

- Mass tactical exits

- Military free fall

• Protects optics when getting service or a replacement is not a now-option.

Tactiholics

Limitations

• Armor Optic uses 0.75 or 1.50 inches of rail space when machined from 6061 aluminum or Type II PVC, respectively.

• Check rail space to determine optimal material.

Two Vets Tripods

Durability

• Matte carbon fiber; when every ounce counts.

• Reinforced matte carbon fiber; fiberglass core insert for superior impact resistance.

• Thin, compact, and chemical resistant.

• Braces use 0.75″ of rail space.

• Superior impact resistance with low impact memory (bounces back to shape).

• Braces use 1.50″ of rail space.

*Spray painted

• Click here for details.

Two Vets Tripods

Installation

Step 1) Insert carbon fiber rods with crossbar into braces.

Step 2) Apply ARP thread lubricant to all bolts including under the bolt head.

Step 3) Position clamps onto picatinny rail.

Step 4) Align braces onto clamps.

Step 5) Insert bolts and tighten to 50 in/lbs.